About me:

In addition to working as a Process Operator, I am also a Shift Coordinator and Shift Manager Deputy. In my spare time I spend a lot of time exercising, for example running different races, besides doing some cooking and carpentry. I started my career at Holmen in the summer of 2002, working as a Winder Operator at PM2 (paper machine 2) and since 2008 I work at PM11 (paper machine 11). I really enjoy working at the paper machine, the various tasks and the shifts.

PM11 - more than just a paper machine

PM11 was brought on stream in April 2002 and at the time it was the fastest paper machine in the world. It remains fast to this day, but over the past 18 years we have also developed a large number of new products for it as well.

Things have changed a great deal in my 12 years with PM11. We began with little more than a handful of products, but now the range is many times broader. Here on PM11 we manufacture everything from low-bleached to high-bleached paper in various thicknesses and grammages. And the latest product is a strong paper that can be used for bags and so on.

It is hugely inspiring to be part of this journey, with so many new and exciting products in the pipeline.

A working day

I begin my working day with the shift handover, when I talk to my colleague about what happened during the previous shift, and whether there have been any switchovers or minor issues with the paper machine. Then we check that everyone is present and correct, since I am also the shift coordinator and there are seven of us in the team – a first operator, a second operator, a dryerman and four windermen. Over a cup of coffee, I go through process images on the screen and check that everything looks normal, make calls to our colleagues at the pulp mill and check that everything is flowing smoothly, and then it is time to take my tour of the paper machine. This allows me to see, hear and feel how the machine is doing today. Once I have done the rounds, we gather in the control room with the daytime team and have a morning meeting.

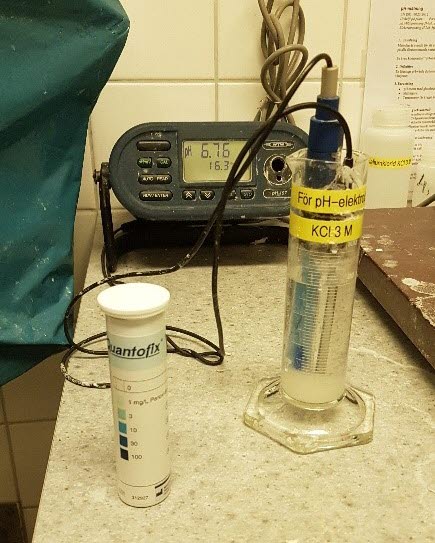

The shift’s other routines then continue from here, with us operators helping with paper testing in the operational lab, LEAN and preventive maintenance on PM11.

On a paper machine no two days are ever the same. Even if we are running a grade that we have run before, the parameters will be different, perhaps due to the quality of the pulp, the speed of the machine and the condition of the felts and wires. We often have a dialogue with our technicians, exchanging new suggestions and ideas on how to optimise the efficiency of the paper machine and other equipment.

We might also have several product switchovers during the shift, so I prepare everything in the process computer and time it so that everything is ready before the switchover occurs. Then I begin summing up the day and write a report in the ProTAK system, ready for the next team to take over an exciting new shift.

Holmen as a workplace – development on many fronts

It is now 18 years since I first joined Holmen and I have the same positive feeling about going to work as I ever did. I am proud of the journey I started on PM2 and am continuing on PM11, with exciting new challenges and new development opportunities.

I feel that as the company constantly develops for the better, it also gives me an opportunity to develop both on a personal level and in terms of working on the paper machine.

Because I also work as a Shift Coordinator and Deputy Shift Manager, I have a great chance to get involved in the whole process from pulpwood to paper manufacture and packaging, and interact with all the colleagues that I don’t see very often. As a major company, Holmen always supports its employees and there are opportunities for everyone to develop in their own fields. If you have the desire and commitment, you can usually try out new areas of work.

Having owners that believe in what we do and the new products that we are developing makes working for Holmen feel very secure, and there are plenty of exciting years to come for me and many others.

Thank you!

We have now come to the end of my week as a blogger. It has been useful for me to think about how to explain my work concisely and to reflect on how lucky I am to be working at Hallsta Paper Mill.

I am really pleased that I get to work with so many great people and colleagues, and I hope you have gained a little more insight into what it means to work on a paper machine.

To everyone reading, I wish you all a wonderful weekend and I will now hand over to the next blogger.

Thank you!