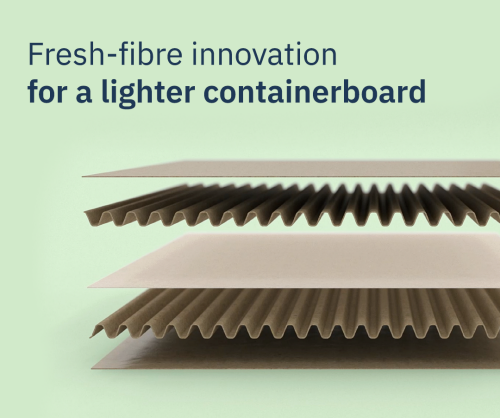

Use Holmen INNR as your light-weight interliner

Look closely at your containerboard components. Reduce excess weight and save carbon dioxide emissions with light-weight interliner.

Technical data sheetWhat is interliner?

The interliner, sometimes called the midliner, is a containerboard component that stabilizes the intermediate layers. It's a complement to the corrugated layers (fluting) and the liner. Holmen INNR is typically used for the second single facer station in the corrugated board production process. There it is adhered directly to the fluted medium from the first facer station. Making up the innermost layer in double or triple wall boards, interliner is used for boxes that are light, yet strong.

For sustainable containerboard

Holmen INNR is a fresh-fibre fluting medium and interliner paper for containerboard. Thanks to the strength of the paper, you can use an interliner in a lower basis weight than your traditional liner paper. It saves cost, since you need to buy less paper, and it saves weight in all transports, also for your customer using the final boxes. And most importantly, using paper in a lower weight will also reduce the total carbon dioxide emissions.

Low weight, smooth surface

Holmen INNR is sturdy for its weight. With its smooth and even surface, the paper runs well through containerboard and paper converting machines. As it's uncoated, it also reacts well to the gluing process, which makes it the perfect interliner paper. And you can use the same paper for fluting if you like.

Read more about Holmen INNR for fluting

Traceable raw materials

100% traceable

With wood fibre based packaging starting to replace plastic, it’s clear that the wood fibre will be an important raw material for a more sustainable tomorrow. As part of the Holmen group we at Holmen Paper have control over the entire supply chain. This means that we can guarantee 100% traceability of the product and ensure that it comes from a growing forest that is sustainably managed. And we have the certificates to prove it.

Direct contact with food

Holmen INNR can also be used safely in food packaging and may stand in direct contact with food. It is certified by ISEGA, according to BfR, Bundesinstitut für Risikobewertung, and adheres to (EC) No. 1935/2004 article 3, 1. (a) and (b). This regulation applies to all food contact materials within the European Union. We recommend that you test sensory properties of the final, converted product.

Environmental data

By switching to a TMP-produced interliner like Holmen INNR, you will reduce both the weight of your finished board, and its carbon footprint. Carbon footprint is calculated as kilograms per tonne.

Carbon footprint INNR

Carbon footprint is defined as the total emissions caused by an individual, event, organisation, or product, expressed as carbon dioxide equivalent. Holmen Paper calculates the carbon footprint of our graphical paper products according to the ten toes of the framework set up by CEPI.

Mill certificates

We operate according to globally recognized standards for forest stewardship and management of environmental, energy and quality aspects.

Chain of custody certificates

FSC® – Forest Stewardship Council® (FSC ID FSC-C020071) – is a system for the certification of forestry, supported by several environmental organisations.

PEFC – (PEFC/05-33-134) Programme for the Endorsement of Forest Certification schemes is an international system for forest certification.

Environment, energy and quality management

ISO 14001, ISO 50001 and ISO 9001 are international standards for environmental management, energy management and quality management.

Occupational health and safety management

ISO 45001 is a standard for occupational health and safety management systems.

Ordering samples from us

The best way to know which paper you want is to hold it in your hand. Our sample packs include both printed and unprinted samples.

Can't see the form? We only ship samples to recipients within Europe – If you are visiting from outside Europe and would like to receive samples of our products, please contact our sales representative in your region.

Find your contact

Holmen Paper UK

Daniel Barrett

Commercial Director

United Kingdom

Send email

Paper Product Development

Jan Andersson

Paper Development Manager

Sweden

Send email

Want to stay updated?

Sign up for The Packaging Paper Loop

Many call us a fast-moving paper supplier for our size. Our products are developed in close collaboration with selected experts, partners and contacts. Sign up for our packaging paper newsletter and get monthly updates about the industry and the progress of our product development.

sustainability

We grow a sustainable future

At Holmen Paper we use the Holmen Group's greatest asset, the forest, to make innovative paper that breaks boundaries and challenges old perceptions. Through sustainable forest management and efficient production processes, we maximise growth and utilisation of the forest raw materials.

Our products are 100% recyclable and form the foundation for sustainable production and recycling. Pulp, paper and paperboard made from fresh fibre from Nordic forests play an important role in the European recovered fibre ecocycle. Since the ecocycle needs a constant injection of fresh fibre, without fresh fibre, there is no future recovered fibre.