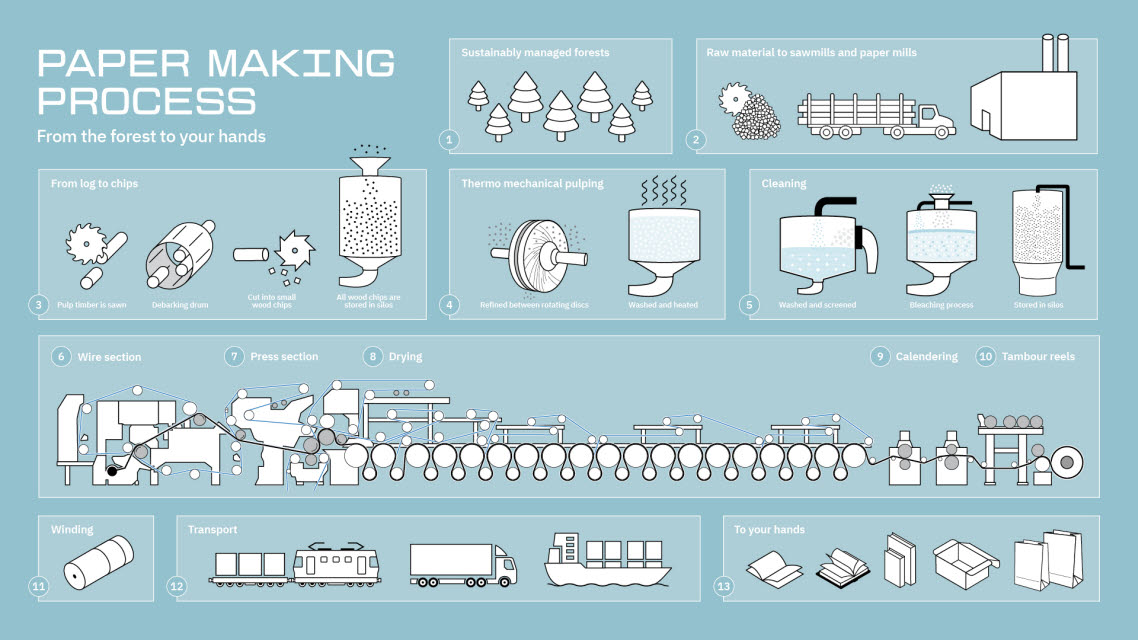

Making paper in a TMP process

How is paper produced? Holmen's paper is produced in a thermo-mechanical pulping process, (TMP). Learn more about paper production in this step-by-step guide with infographics and videos.

Making high-quality, sustainable paper in an efficient TMP process

Thermo-mechanical pulping, or TMP, is a high-yield, energy- and resource-efficient technology for splitting larger wood chips into individual papermaking fibres. These fibres are then laid out in a very thin sheet on the paper machine, to produce high-quality paper with high bulk, strength and brightness properties to perfectly meet the needs of paper users.

The TMP process is resource efficient in two ways. First, it provides an extremely high yield of around 97%, meaning of the original woodchips going into the process 97% come out as usable paper fibres. This is extremely high compared to many other wood pulping processes.

Second, although the TMP process requires high electrical energy input to accomplish the fibre splitting or refining step, the majority of that energy is recovered as heat.

This valuable thermal energy is then recycled numerous times, both upstream for preheating of the woodchips, as well as for drying of the paper on the paper machine. It can be recovered once again for heating of ambient air in the production plants and offices.

Quite often the steam you see coming out of a paper mill is 100% water vapour, from which all the useful thermal energy value has been extracted.

From pulpwood logs to chips

Pulpwood logs come from sustainable forests located quite close to both of Holmen's mills, normally within a radius of about 150 km. This is positive for two reasons, first it keeps the transport distances, and associated fuel emissions, low. And second, it means the wood is quite fresh when arriving at the mill which helps produce higher brightness paper.

The logs are then fed into the massive debarking drum, which removes the bark, which is not useful for papermaking but is a very good biofuel that can be used both at the mill or sold to other power generating companies for burning as a biofuel.

The logs then go through screens to remove any stones or metal objects that could be harmful to the process.

Next, the debarked cleaned logs are then fed into the chipper, which is an immense, rapidly rotating disc plate containing razor-sharp knives. The chipper chews up the logs at the incredible rate of 1.3 m/sec, cutting them into small woodchips measuring 22 mm wide and high, with a thickness of 5-6 mm. Following careful screening of the chips to ensure they are all approximately the same size, they are then sent to massive storage silos, before the pulping step.

Please accept Marketing cookies to view this content.

Play

Can't see the video? You need to accept marketing cookies to be able to see the video. Or click here to open the video in Youtube.

From wood chips to pulp

The TMP refiner, which is like a high-tech version of an old coffee-grinder, is the heart of this phase. The chips are transported from the storage silos, passing through a water washing process, and then heated with steam to soften the lignin, which is the glue which holds wood fibres together. The uniform, heated chips are then fed into the TMP refiner using a high-pressure screw feeder.

The TMP refiner consists of two stages where two giant metal grinding plates, one stator and one rotor, with intricate grooved patterns are rotating at approximately 1500 RPM. The gap between the plates is only 0.6 mm, thereby shredding the chips into papermaking fibres while the intricate patterns ensure that the fibres are separated in the lengthwise direction instead of being cut into dust. The aim is to produce long straight fibres that are slightly brushed on the surface to produce what is called micro-fibrillation, but without cutting them up into short fragments.

The combination of woodchips, water, steam, and energy going through the tiny 0.6 mm refiner plate gap generates high-temperature and high-pressure steam, which is recovered as described above.

The pulp, or papermaking fibres, are now screened to make sure they are all separated from each other and then bleached to get an acceptable level of brightness.

TMP fibres are much stiffer than many other grades of pulp, which give key benefits to the paper sheet. For example, they provide paper used for books with high bulk and high stiffness properties, resulting in a high-quality comfortable feel for the user.

In the next step, you will see how to the pulp finally becomes finished paper.

Please accept Marketing cookies to view this content.

Can't see the video? You need to accept marketing cookies to be able to see the video. Or click here to open the video in Youtube.

Pulp to paper

The paper machine is always the heart of any paper mill. On the paper machine, the fibres which have been mixed with large quantities of water are laid out in a very thin layer on an endless-band meshed screen, with a weave similar to a mosquito net. The water is then successively removed, so that the “stock” mixture which is 99% water and 1% fibre at the start, is about 93% fibre and only 7% water in the final sheet. The paper machine performs this fascinating transformation.

To do this, the fibres are mixed with chemicals and fillers and much water to form the stock with 1% fibre. This is then ejected from the headbox in a fine thin rectangular jet at the enormous rate of 2,000 litres per second and a speed of 100 km per hour. The jet lands in the gap between the two meshed screen or forming fabrics. Water is first drained by gravity and then pulled out with vacuum suction boxes, raising the sheet to 20% fibre.

Next, more water is harshly but carefully pressed out between spongelike felt surfaces bringing the fibre content up to 50%. Finally, the sheet is threaded over large steel steam-heated cylinders at 135°C to evaporate the remaining water, so we end up with approximately 93% fibre and 7% water in the final sheet.

To achieve the perfect paper quality, two key steps are vital. The first is continuous online quality scanning, and the second is what’s called calendering, a smoothing process to remove bumps and creases. Quality scanning is done by the QCS, which is a high-tech monitor travelling back and forth across the sheet while measuring all the key paper properties. These include the weight in grams per square meter, the brightness or whiteness, the thickness and the amount of mineral fillers. Advanced data analytics then make sure that all these properties are within the specifications in all directions on the sheet. This is critical for getting a consistent and uniform printing surface and high-quality feel to the paper.

Calendering is a smoothing process done at the end of the paper machine in which a hard heated metal surface presses the paper against the softer backing roll to make the sheet smooth and glossy and also to keep the sheet thickness consistent. The process is somewhat like ironing of a shirt on an ironing board, but on a vastly larger scale.

Finally, the paper is wound on the jumbo reel which is a giant roll of paper weighing up to 40 tons, with a length of about 100 km. This is then slit into smaller rolls for delivery to customers.

Please accept Marketing cookies to view this content.

Can't see the video? You need to accept marketing cookies to be able to see the video. Or click here to open the video in Youtube.