Holmen’s forestry is certified to the PEFC and FSC® standards (FSC_ID) and all the wood is fully traceable.

Read more here

Wood is a naturally renewable and energy-efficient raw material. Holmen’s wood products come from sustainably managed forests and are refined in our chain-of-custody certified sawmills.

Wood is the only construction material that is 100% renewable. Since wood products have the capacity to store carbon dioxide for a long time, wooden buildings are significantly better for the climate than those built using fossil-based materials and processes. Producing steel and concrete creates considerable emissions of fossil carbon that affect the climate.

Using wood contributes to sustainable development. Replacing fossil materials with renewable structural components in wood creates climate benefits on many fronts. Emissions of greenhouse gases from manufacturing and using climate-negative materials are avoided, while increased use of products from the forest captures more carbon dioxide. In addition, the whole chain from manufacture to transport is much more energy-efficient and cost-effective.

The growth of the forest and its value largely depend on how it is managed. Under Holmen’s active forest management, the volume of standing timber is built up over a period of 70–90 years, with a new growth cycle beginning after harvest. Many of the most important silviculture measures come in the years after harvest, when the soil is prepared and the land is reforested through planting or sowing. We clean and thin the forest in order to select trees with the best potential for further growth.

Around 10–30 years before the forest is ready for harvesting, it may be fertilised to further enhance growth. The annual harvest equates to 80 per cent of the forest’s growth, which means that the amount of wood in our forests increases year on year. For every tree we harvest, we plant at least two new ones. Our forestry is certified to the PEFC™ and FSC® standards and all the wood is fully traceable.

Please read more about our sustainable forest management.

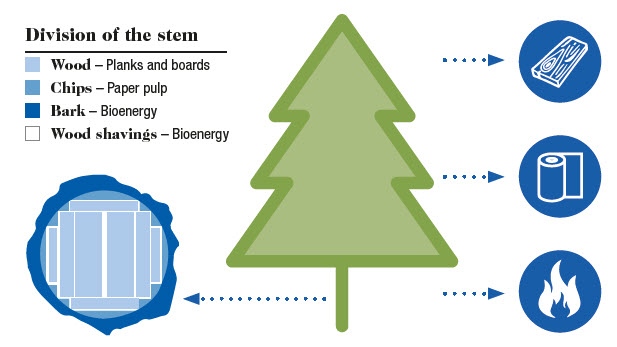

Our wood products value chain runs all the way from tiny seed to finished timber building. Our high-tech sawmills use the entire log. Nothing goes to waste.

Holmen’s forestry is certified to the PEFC and FSC® standards (FSC_ID) and all the wood is fully traceable.

Read more here