Reduce, reuse and recycle are three pillar stones for the Packaging and Packaging Waste Regulation (PPWR). Even though the details for the regulation's implementation are not yet fully settled, we recommend actors and buyers on the packaging market to design, innovate, and develop in this direction.

What will PPWR mean for containerboard and plastics?

Reduce packaging, and above all – reuse, or use recyclable materials. PPWR (the Packaging and Packaging Waste Regulation) sets out to transform packaging. Lightweight containerboard will lead the way to the circular society.

How containerboard brings solutions

Lightweighting opportunities

PPWR cuts packaging volume. Use lightweight containerboard, consume less raw material for your packaging.

Recyclable food-contact packaging

A producer has full control over the contents in a fresh fibre material. Substitute single-use plastics.

Quickest way to circularity

By 2030, all packaging should be reusable or recyclable. Containerboard has the best recycling rate.

Conscious choices help the industry

The Packaging and Packaging Waste Regulation (PPWR) focuses mainly on three things: minimizing packaging, increasing recyclability and recycled content, and phasing out certain single-use packaging.

What will the consequences will be for the pulp and paper industry? For packaging producers? And for the consumers?

Let's look at the aim behind PPWR, as stated on the EU Packaging waste webpage to shine some light on this. For us who work in a fibre-based packaging value chain – as part of a biobased industry – PPWR brings enormous opportunities to step up and take a lead.

Let's focus on the aim of PPWR, which you can see here below. Click to expand the view and read about the implications for the industry:

"The aim is to minimise the quantities of packaging and waste generated ..."

Packaging needs to be able to fulfil its purpose with as small environmental impact as possible. Efficiency equals value, and the consumer will never benefit from waste, so this part will serve the consumers in the end.

"... while lowering the use of primary raw materials ..."

The call for material efficiency and innovation pushes the industry to make better use of resources. This doesn't mean stepping away from fresh-fibre-based containerboard, because an input of recyclable fresh fibre materials will always be needed to keep the cycles running.

The development of high-yield materials (such as Holmen's lightweight containerboard components) means that less raw material will be needed to provide the same level of protection for the goods. An industry that makes better use of the resources will serve its customers, owners, employees, and end-consumers very well in the long run.

"... and fostering the transition to a to a circular, sustainable and competitive economy."

Containerboard and paperboard are the main players in circularity because their recycling is so well-established all over the world.

This cycle starts with raw material from a renewable source, where the fibre comes from by-products of wood industry and sustainable forest management in a carbon-capturing forest cycle. Fibre-based materials are part of the green transition since they help us move away from fossil dependence.

Reduce

The overarching plan is to reduce the global carbon emissions and reach net zero by 2050. To achieve this, PPWD has set targets for the European market to reduce packaging: 5% by 2030, 10% by 2035 and 15% by 2040. This may not seem so difficult to achieve, but the packaging volume is still in a growing trend, based on increased consumption, goods transportation, and e-commerce.

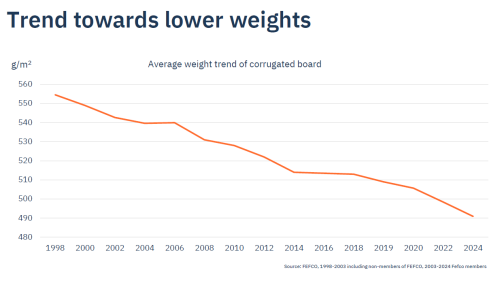

The efficient use of materials like containerboard is encouraged to minimize waste. And data from FEFCO shows that even though the volume is increasing, the average weight of corrugated board decreases.

PPWR's reduction targets apply to all packaging, made from fibre-based or plastic materials, glass, metal, or composites. Plastics, however, is also covered by another regulation, the Single-Use Plastics Directive (SUPD), in order to combat the environmental harm caused when it ends up in nature or in the sea as litter.

The SUPD and the PPWR have to be aligned to work as intended and support a well-functioning material loop. Therefore, the current update of SUPD will need to be finalised (estimated in 2026-27) before the implementation details for PPWD will be fully defined.

How can we help reducing the packaging material?

Working with lightweight materials is the way forward. We need to keep momentum for the fibre-based lightweight mindset within our industry. Be brave, and challenge the existing standards. Lighter packaging will also emit less CO2 and cost less to transport, so these efforts will answer to many goals.

Reuse

Part of the packaging waste can be avoided by reuse and refill systems.

Hotels, restaurants and catering businesses (HORECA sector) will be required to allow consumers to bring their own reusable containers for takeaway food from 2027, according to the regulation (article 32). They will also need to offer reusable food and beverage containers to their customers free of charge from 2028 (article 33).

A ban on several specific types of single-use plastic (SUP) packaging is planned to apply from 1 January 2030, including plastic packaging used for fruits and vegetables.

By 2030, the aim is for all packaging to be either reusable or recyclable. This is less than five years forward in time.

What can containerboard do?

Plastics may be the better suited material for reusable food and beverage containers today. But since the producer has full control over all the contents in a fresh-fibre-based material, it's a natural go-to for making all kinds of food contact-safe products, on top of being lightweight and recyclable. We use more and more paper-based solutions for food trays, sleeves, and all types of packaging to protect, carry, and transport HORECA sector goods.

Here's an interesting area for future design and innovation.

Recycle

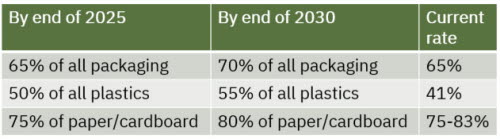

When PPWR was formed, it was decided that packaging should be recyclable, fulfilling strict criteria to be defined through secondary legislation. But for this to make a difference, the recycling rates for all materials needs to be satisfactorily high. Therefore, PPWR has set targets for the recycling rate, by weight of packaging waste, for the total as well as for different materials.

The recycling rate target for paper packaging is the highest among all the materials, and in absolute volumes, more paper packaging is being recycled than all the other packaging materials combined.

Source: EU, 2022 (all packaging), Eurostat/CEPI, 2022-2024 (plastics, paper)

As can be seen from the table, paper and cardboard is already in line with the PPWR 2025 target, while recycling of plastics has a large gap to cover. This is the reason why the PPWR has included minimum targets for recycled content for all plastics in packaging, spanning from 10–35% in 2035 (depending on the polymer and application), up to 25–65% in 2040.

On top of this, PPWR includes specific rules to limit the use of composite materials which cannot be separated manually, to label the materials correctly, and to assume extended producer's responsibility (EPR), if all parts of the regulation follow through.

In conclusion, recyclable fibre-based materials such as containerboard and paperboard are well set to fulfil the demands in the Packaging and Packaging Waste Regulation (PPWR) by answering to both reduction and recyclability targets.

Design for recyclability

A product's environmental impact is greatly influenced by its design. Containerboard components and a design strategy based on DfR, Design for recycling, can help you future-proof your packaging. Less waste will be sent to landfill or incineration, and the materials can be re-used when manufacturing new products.

Read more about our offer

Reduce packaging weight without compromising on strength or print quality with Holmen Elevate.