Many interests must coexist in the forest – forestry, reindeer husbandry, hunting and outdoor life. At the same time, the forest is a habitat for animals and plants. Holmen conducts future-smart forestry that balances these interests, today and for the future.

How we contribute to the climate

Our climate benefits are increasing through a growing business

The forest is most useful when it is used. This is the core of Holmen's business and our goal is to increase our contribution to the climate transition throughout our value chain. Above all, by increasing the positive impact of our operations, but also by reducing our negative footprint.

Growing forests bind carbon dioxide

Young trees have the greatest ability to bind carbon dioxide. Through active forestry, where the trees are harvested when growth slows down and the land is then reforested, we increase the forest's growth and absorption capacity over time.

Products with a low carbon footprint

The real estate sector is responsible for more than a third of Europe's carbon dioxide emissions, and it is both expensive and difficult to make the production of the dominant building materials cement and steel sustainable. Wood is a renewable alternative that, unlike cement and steel, is also energy-efficient to produce while storing carbon dioxide in buildings.

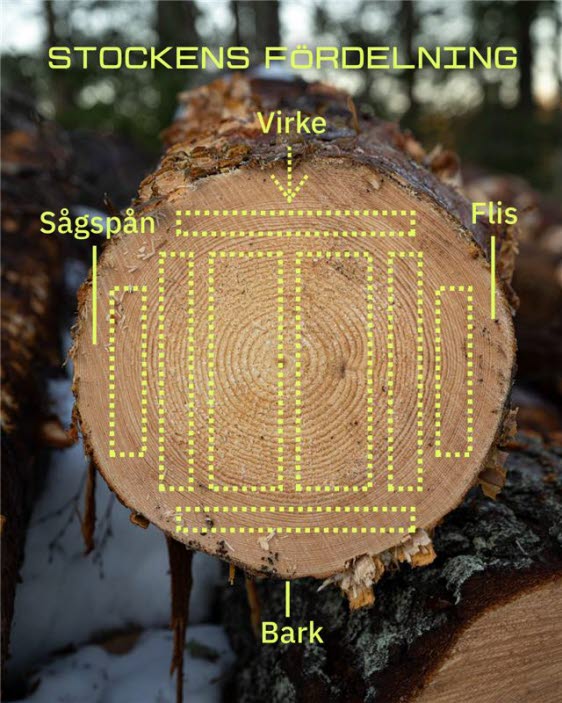

We take care of the whole tree

The value chain in our wood products runs all the way from seed to finished wooden house. The entire log is utilised in our high-tech sawmills. Nothing is wasted.

5%

Branches, tops, bark and sawdust become renewable bioenergy that can be used to produce electricity, heat and biofuels.

45%

The thinner part of the tree and timber from thinning are ground or boiled down into pulp that is used for the production of paper or cardboard.

50%

The coarse logs, which make up half of the harvest, go to sawmills for the production of building materials in the form of construction timber and carpentry products.

Holmen's biocombinate

Holmen's production facilities are biocombined. A combined means that an industry produces several different products from the same raw material. Holmen's sawmill and paper mill in Braviken and the sawmill and paperboard mill in Iggesund are biocombined.

Here we produce several different bio-based and renewable products from the forest. The entire tree is taken care of. Planks and boards are sawn. Wood chips from the sawmill become raw material in pulp production at the paper mill and the board mill, respectively, and by-products such as bark and dry chips become biofuel that is converted into energy and district heating. The circle is closed when hot water from the paper mill and steam from the paperboard mill are used in the drying processes at the sawmills.

The sawmills in Braviken and Iggesund are thus part of a bio combination with Braviken's paper mill and Iggesund's paperboard mill respectively. The biocombines provide synergies that reduce the environmental impact. By-products such as bark and dry chips from the sawmills are used in the mills' solid fuel boilers, and fossil-free energy in the form of heat and steam is generated.

The sawmills buy heat from the mills for their drying process, and waste heat is used to heat production premises. Increased production with high raw material utilisation results in increased deliveries of renewable biofuel. Streamlining energy use reduces environmental impact.

Climate effects that make a difference

Why is wood good for the environment? Wood is a naturally renewable and energy-efficient raw material. Holmen's wood products come from sustainably managed forests and are processed in our chain of custody-certified sawmills.

Wood is the only building material that is one hundred percent renewable. As wood products have the ability to store carbon dioxide for a long time, buildings made of wood are significantly better for the climate than those made with fossil-based materials and processes.

The use of wood contributes to sustainable development, and by replacing fossil materials with renewable building elements made of wood, climate benefits are created at several stages. Greenhouse gas emissions from the manufacture and use of climate-damaging materials are avoided, while increased use of products from the forest binds more carbon dioxide.

In addition, the entire chain from manufacturing to transport becomes significantly more energy-efficient and cost-effective.

Certified wood

Certified wood from sustainably managed forests and chain of custody-certified sawmills are important parts of Holmen's long-term environmental work. But what are PEFCs, FSCs® and EPDs? Here we list our different certifications and what they mean.

Prejudices about forestry

Products from the forest are replacing fossil alternatives. They will be used for climate-smart schools, offices and apartment buildings, and will be of great benefit to society, while limiting negative climate change.

In addition, there is actually more forest in Sweden today than there was a hundred years ago. Something we can thank responsible harvesting, reforestation and long-term forest management for.

Despite these truths that are as measurable as they are obvious, prejudices abound that Swedish forestry is not sustainable. In fact, Swedish forestry is perhaps the most responsible in the whole world. We asked Jan Åhlund, forest specialist at Holmen Skog, for help in clearing up some myths about the forest.

Forestry and wood construction - what is true? - Holmen Wood Products

Read more

Here you can read more about how we work for a sustainable future.

Read more

Here you can read more about how we work for a sustainable future.