Who am I?

Hello colleagues! It’s my turn to share what I do in our employee blog, which is a real treat. So who am I? My name is Ragna Orbe, I’m 38, and I work at Holmen’s paper mill in Hallstavik as a laboratory assistant in the Main lab. I’m now in my fifth year here at the mill and I really enjoy where I work.

I live a way outside Hallstavik, on a farm with my partner, two children, and two dogs. When I’m not working, I spend my time with my family and friends, preferably out in the countryside. I also enjoy reading books and these days I’m mostly into fantasy as a genre.

The Main laboratory as a workplace

Twelve people work in the Main laboratory: a section manager, a lab engineer, two lab technicians, and seven lab assistants. We do a lot of routine testing (quality assurance) on the whole process, taking samples and analysing everything along the production line – the wood, the pulp, incoming and outgoing water, process water, and the finished paper. The laboratory is Swedac accredited, so we also handle the analyses of emission values that we report to the County Administrative Board, which includes sampling the receiving water, and taking samples from the surface water and groundwater pipes. In addition, we handle checks of the mill’s lab instruments, work orders from our internal customers, complaints cases, and trials (both lab-scale and full-scale).

Our work is therefore very broad, involving a lot of problem-solving and requiring good communication with our customers.

A working day at the Main laboratory

The working day starts first thing in the morning at seven. I check my emails, then we have a morning meeting at 7.15 am at the work planning board, led by our section manager. This is our opportunity to check that everyone knows what their tasks are for the day, to go through any extra safety and security issues we need to think about, and to establish whether there is any other important information we need to keep on top of during the day/week. Then we have ten minutes of morning exercise.

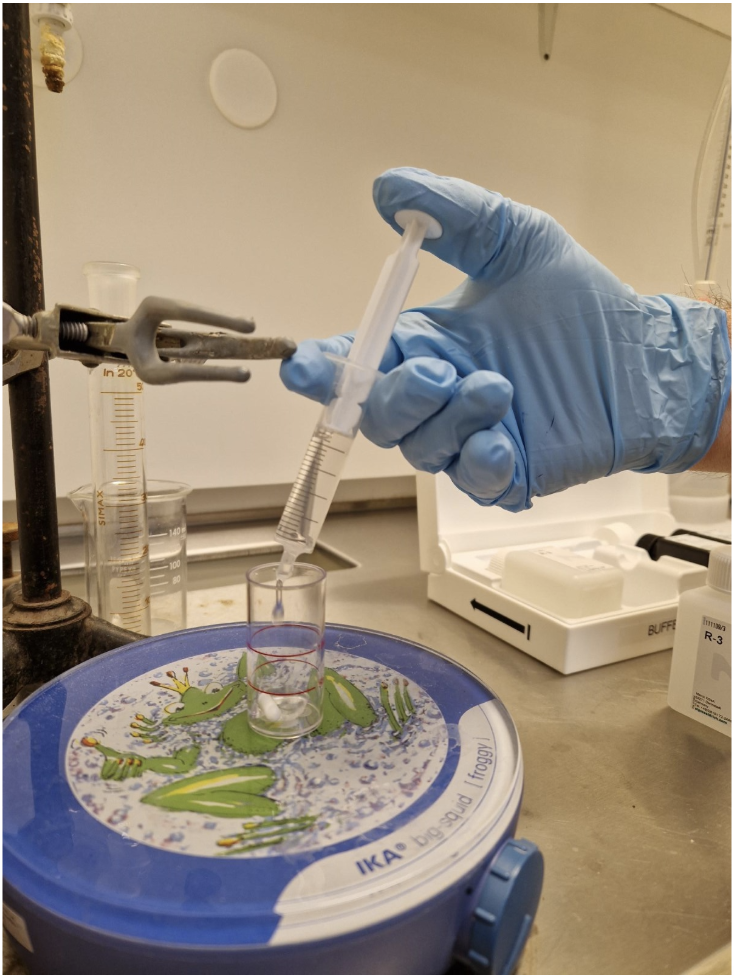

After that, I begin the day’s sample collection around the mill. Depending on the testing areas I have scheduled for the day, there may be more sampling rounds later on, which means I can hit over 10,000 steps in a working day. Once I’m back in the lab, it’s time to analyse the samples. Before that, though, I check the equipment and instruments I’ll be using – for example, using a buffer solution to check the pH meter, or checking that the pipettes take the correct volume. The results are then reported in our internal systems, and if there are any nonconformities, they’re also reported in ProTak so that internal customers can take action.

And before heading home, I wash all the sample containers and clean down the work surface. I often also prepare for the next day’s sampling, so when I arrive in the morning, I can get started straight away.

Why Holmen?

I really enjoy my job. We’re involved in so many different areas, and no two days are quite the same. The longer I’ve worked here, the better I’ve got to know the process and my colleagues at the mill. Paper manufacturing is a complex process with many factors at play, which makes my job very exciting.

I’m learning new things all the time, and I feel that I’m helping to maintain the function and quality of the process. I constantly face problem-solving challenges, and there are plenty of experienced people to bounce ideas off.

And best of all, there are my colleagues in the lab, who are fantastic!

Finally

I’d like to thank you for giving me the floor, and the opportunity to tell you about what I and our department do every day. I hope you found it interesting and informative.

/ Ragna